ENGINE OF YOUR BUSINESSELEKTROPROMREMONT

OUR SERVICES

Elektropromremont was founded in early 1998 and is one of the leading and dynamically developing electrical repair enterprises in Ukraine.

Our enterprise offers the services in capital, average and current repairs of electric motors of all capacities and designs, production of spare parts, and also diagnostics of electric equipment.

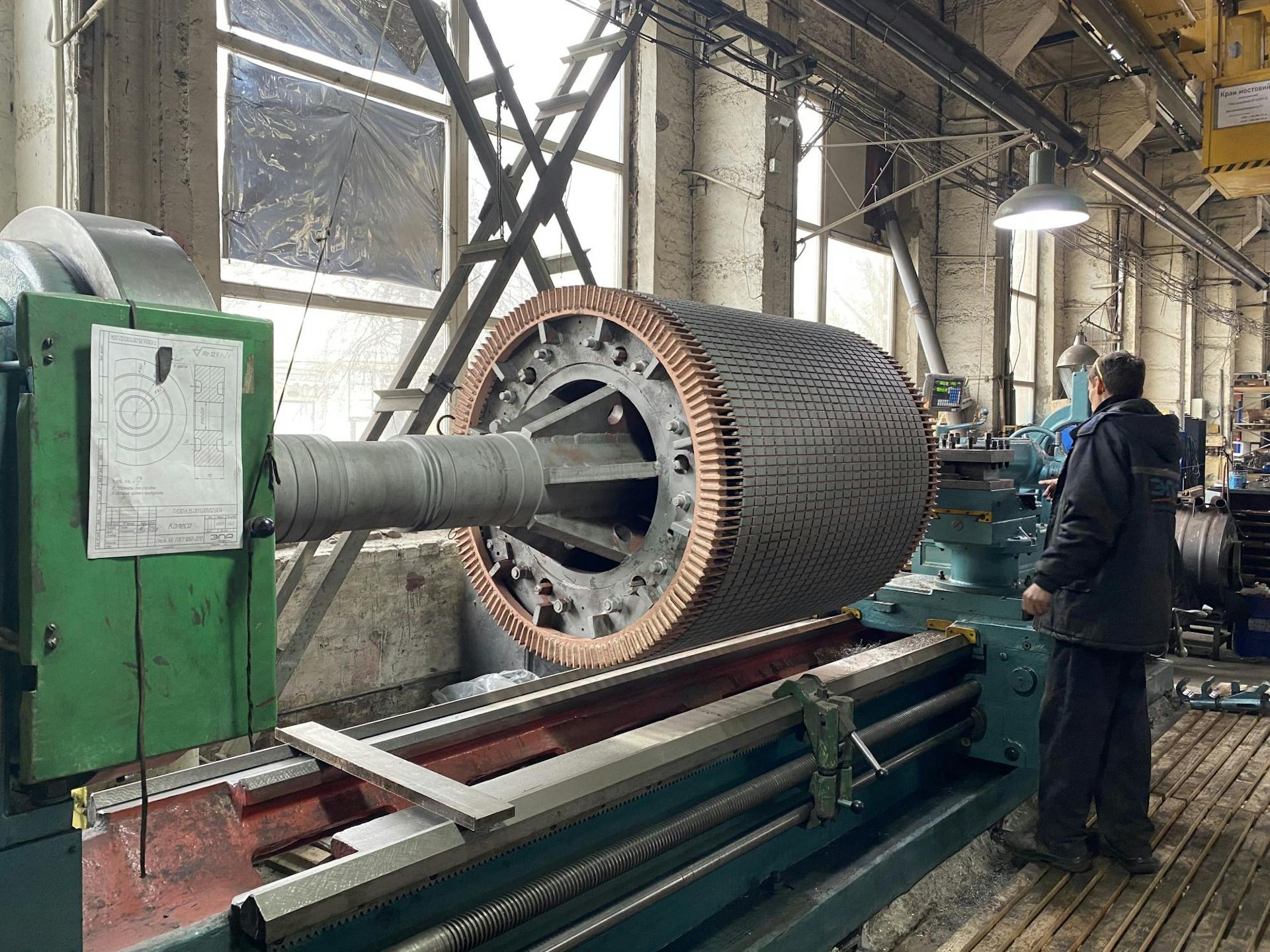

Repairs of electric motors involves disassembly, cleaning of parts and assemblies, detailed defective, replacement of the windings of the stator and rotor of the motor, machining of seats, bearing units, bearing replacement or repair of bearings. If necessary, fans, flanges, bearing shields, and junction boxes are repaired. Depending on the test results of the stator active iron, it is possible to manufacture and replace multilayer stator and rotor cores. A prerequisite for repair is balancing and control exhaust tests with scrolling at idle.

REPAIR OF ASYNCHRONOUS ELECTRIC MOTORS

We carry out repair of asynchronous electric motors of any complexity, namely:

- Repair of high-voltage asynchronous electric motors with insulation "Monolith";

- Repair of high-voltage asynchronous wedge-free electric motors;

- Repair of high-voltage asynchronous explosion-proof electric motors;

- Repair of asynchronous motors with a phase rotor;

- Repair of asynchronous squirrel-cage electric motors.

REPAIR OF SYNCHRONOUS ELECTRIC MOTORS

We offer you performance of works on repair of synchronous electric motors both on our production base, as well as in the place of installation, with large dimensions and complexity of transportation, namely:

- Repair of high-voltage synchronous motors with pronounced poles;

- Repair of synchronous hydro generators;

- Repair of turboelectric motors and turbogenerators;

- Repair of traction synchronous generators;

DIRECT CURRENT ELECTRIC MOTORS

Our enterprise offers to repair electric DC motors with power from 5 kW to 10,000 kW, weighing up to 100 tons, for metallurgical enterprises, mining and processing plants, cement enterprises and other companies.

- Repair of rolling large-size direct current electric motors;

- Repair of electric motors of a direct current of an excavator group;

- Repair of direct current generators;

- Repair of crane direct current motors;

- Repair of traction electric motors and traction direct current generators;

PRODUCTION OF SPARE PARTS FOR ELECTRIC MOTORS

Elektropromremont is a manufacturer of spare parts for electric motors, carrying out a full range of works on the development of design documentation, final control tests, installation supervision, as well as delivery to any part of Ukraine and the world.

Today we are ready to offer you production of the following spare parts to electric motors:

- TypesOfProcurement of stator winding sections for synchronous motors;

- TypesOfProcurement of stator winding sections for asynchronous motors;

- TypesOfProcurement of stator winding sections for low-voltage electric motors;

- TypesOfProcurement of coils for synchronous rotors of any size and complexity;

- TypesOfProcurement of coils for synchronous rotors of any size and complexity;

- TypesOfProcurement of coils main and additional poles for direct current motors;

- TypesOfProcurement of cores of the rotor crane motors and the compensation windings;

- TypesOfProcurement of collectors of electric direct current motors;

- TypesOfProcurement of bearings racks;

- TypesOfProcurement of plain bearing shells;

- TypesOfProcurement of oil lubricating rings for plain bearings;

REPAIR OF ELECTRIC MOTORS WITH BULK WINDING

Our company offers repair services for low-voltage electric motors with bulk winding power from 1 kW to 320 kW. This nomenclature group includes electric motors with short-circuited and phase rotor for general industrial purposes, crane electric motors, as well as electric motors of imported production.

FIELD WORK

We can repair especially large electric motors that are problematic to transport at the installation site, both in Ukraine and in other countries.

Field work is always associated with adaptation to the requirements of the customer's services, with production and domestic difficulties, but the specialists of our company can solve these problems, and always strive to perform the work in a short time.

We carry out repairs at the installation site of mill synchronous electric motors (including their dismantling and installation), racing motors and generators (including collector grooves) of the Ward-Leonard system of rolling shops, low-speed vertical electric motors of pumping stations, hydroelectric power plants of hydroelectric power stations and others.

When performing all work at the installation site, phased control is carried out using its own mobile testing station.

OTHER SERVICES

Mechanical processing

We carry out mechanical processing of worn and damaged parts and components of electrical machines during operation, by means of surfacing and subsequent processing on screw-cutting, milling, drilling and other machines.

We defect, restore and manufacture:

- Seats of bearing shields, axle boxes;

- Seats on the shaft of rotors, anchors;

- Flanges, labyrinth bearing seals;

- Mechanical processing of sliding bearings to the size of the bearing journals of the rotor shaft;

- Defective parts and assemblies.

Balancing rotary equipment

During the operation of electrical parts, increased vibration parameters arise, which over time leads to the destruction of the main components of electrical machines. The imbalance of the system of mechanisms, rotating parts of electrical machines makes up most of the causes causing an increase in vibration parameters.

Our enterprise has the ability to perform both static and dynamic balancing of the rotating parts of electrical machines and mechanisms. The enterprise is equipped with modern balancing devices designed to balance the rotating parts both on the machine and in their own bearings, and specialists performing balancing of the rotating parts have undergone special training in training centers in Ukraine.

We perform static and dynamic balancing of rotor equipment (rotor, anchors, fans, impellers and others) on a balancing machine in the enterprise, as well as at the place of its installation.

The maximum possible mass of the rotating parts for balancing on the machine is 5000 kg, the minimum is 80 kg. The maximum possible length is 2500 mm.

MEASUREMENTS AND TESTS OF ELECTRIC MACHINES.

Diagnostics of electrical machines.

According to the project area measurements applied to the Certificate of technical competence test station, the test station carries out measurements and tests on electrical following parameters:

ELECTRIC ROTATING MACHINES:

- Measurement of the insulation resistance;

- Tests of case insulation with increased voltage of industrial frequency;

- Measurement of resistance of a winding to direct current;

- Testing of winding insulation of windings by pulse voltage;

- Check of work idling;

- Measurement of the vibration of electrical machines;

- Test of active stator iron;

- Measurement of rotational speeds;

- Measurement of bearing temperature.

GROUNDING DEVICES:

- External inspection of the visible part of the grounding device;

- Inspection with a check of the circuit between the ground electrode and grounding elements;

- Measurement of resistance grounding device;

- Measurement of “phase-zero” impedance.

ELECTRICAL INSTALLATIONS, DEVICES, SECONDARY CHAINS AND ELECTRICAL WIRING WITH VOLTAGE UP TO 1000V:

- Measurement of insulation resistance;

- High voltage test of insulation of electrical products, live cable of a hand tool;

- High voltage insulation test of power and lighting wiring;

- Checking the presence of a circuit between grounded installations and elements of the grounding installation;

POWER CABLE LINES:

- Determination of core integrity and phasing;

- Test of high voltage;

- Determination of ground resistance;

- Test of protection operation of machines up to 1000V with grounded neutral.

Stationary and mobile test facilities of various capacities (P = 2.5 kVA, 3.0 kVA, 15 kVA, 35 kVA) allow testing electrical equipment and other devices with an alternating voltage of industrial frequency up to 35 kV, during repairs on the premises, as well as during repairs at the place of installation.

Stationary stands and measuring instruments of the test station make it possible to check the parameters of electric machines with alternating and constant voltage up to and above 1000 V, with power up to and over 1000 kW at idle.

To determine the causes of increased vibration, vibration analyzers are used to make a comprehensive analysis, both in terms of the general level and vibration spectra.

Skilful use of the results of measurements, tests and vibration analysis by specialists of enterprises allows to carry out high-quality diagnostics of an electric machine, thereby preventing its premature failure.